Cost and efficiency are probably the most important factors for successful fleet management. And preventive maintenance directly benefits both. Not only can it minimise vehicle downtime, but also avoid costly breakdowns to ultimately improve the bottom line of the business.

So, to help you keep your fleet running smoothly we’ve prepared a quick guide to introduce commercial vehicle preventive maintenance.

What is preventive maintenance?

Preventive maintenance is a proactive approach to vehicle upkeep, for instance: scheduled servicing, vehicle inspections, or part replacements. In other words, it’s about fixing a problem before it becomes a problem. With the purpose of keeping commercial vehicles in top shape, maximising efficiency, and lowering costs.

The process itself is usually built around a routine and can be split into two traditional approaches: time-based – periodic vehicle maintenance, based on predefined time intervals (e.g., monthly, quarterly, yearly), and usage-based – routine maintenance, which is guided by vehicle usage (e.g., every 4000 miles).

However, driven by technological innovation within the sector, a new and arguably better approach to preventive maintenance has been introduced. Which some define as – prescriptive or predictive maintenance. Essentially, this approach utilises machine learning and AI to monitor and process vehicle data to severely reduce operational risks.

For example, tools like Jaltest Telematics, utilise this technology to estimate the lifetime of vehicle components based on operational history, provide early warnings of failures, and can even recommend the most optimal maintenance times. Whilst reducing fuel consumption and maintenance costs overall.

What are the benefits of preventive maintenance?

There are quite a few benefits that come with the implementation of preventive maintenance.

Reducing costs and preventing downtime

As with a lot of innovations in business, they’re developed with the goal of reducing expenses, whether it’s directly or indirectly. And preventive maintenance is no exception to that rule.

It has become especially beneficial nowadays, due to continuously rising vehicle maintenance costs because of the Covid-19 pandemic and the Russian invasion of Ukraine. Not only have petrol prices skyrocketed, but the same extends to other vehicle-related costs.

Regardless, introducing preventive maintenance to your fleet can support you in driving the expenses down. By regularly scheduling maintenance & repairs, you can prevent more expensive vehicle failures, reduce fuel consumption, as well as avoid costly downtime.

The example of the consequences of light commercial vehicles (LCV) downtime in the UK does well to illustrate the severity of this problem – it can cost you as much as £800 a day. Not to mention, that UK businesses collectively lose around £2.4 billion a year due to LCV downtime. And that’s only the smaller commercial vehicles… So, as you can clearly see – downtime equals lost money.

Overall, a tool like Jaltest Telematics can help you optimise the way you run your fleet, reduce the risk of unexpected expenses, and bring new levels of efficiency.

Enhanced vehicle lifetime and reliability

To put it simply, the longer you keep a vehicle running – the more value you’re getting from the investment. By utilising preventive maintenance, you’re investing in the long-term condition of your fleet. For instance, if you address minor faults immediately, you’ll not only prevent bigger failures from forming but also reduce the overall wear and tear on the vehicles.

Fundamentally, preventive maintenance extends vehicle lifetime and keeps them in tip-top condition, which in turn, creates a sturdy, efficient, and reliable fleet.

Improved safety and regulatory compliance

By conducting regular preventive maintenance, you’ll make sure that the commercial vehicle fleet is in compliance with regulatory requirements. Which will allow you to avoid any unexpected fines.

In a similar vein, you can ensure that all the fleet’s vehicles are safe for drivers and passengers alike. Considering that through preventive maintenance you can minimise the risk of accidents and injuries, among other legal liabilities.

Streamlined planning and scheduling

A streamlined management process is especially supported by tools like Jaltest Telematics and predictive maintenance. For instance, by having the ability to remotely anticipate maintenance needs, fleet managers can schedule vehicle maintenance during off-hours – improving overall efficiency.

Moreover, due to the availability of substantial vehicle data, the system can recommend which maintenance tasks take priority, reduce administrative workload by automating tracking and scheduling, as well as enhance overall decision-making. All in all, by streamlining the maintenance processes and communication – fleet managers can focus more of their time on ensuring the optimal efficiency of the fleet.

How to implement a preventive maintenance program?

Implementation of a predictive maintenance program using Jaltest consists of a few key steps, which we’ve outlined below. Although, if you want to enquire about expert assistance – feel free to contact our team. Which can walk you through the purchasing & implementation processes, as well as provide additional training.

Assess the current situation

The first step in putting a Jaltest predictive maintenance programme into place is to evaluate your present maintenance procedures. Reviewing existing maintenance processes, looking for any gaps or inefficiencies, and figuring out how predictive maintenance might aid your current activities are all part of the process.

Set up the system

Setting up the Jaltest system is the next stage. With the goal to gather and examine vehicle information from numerous sources:

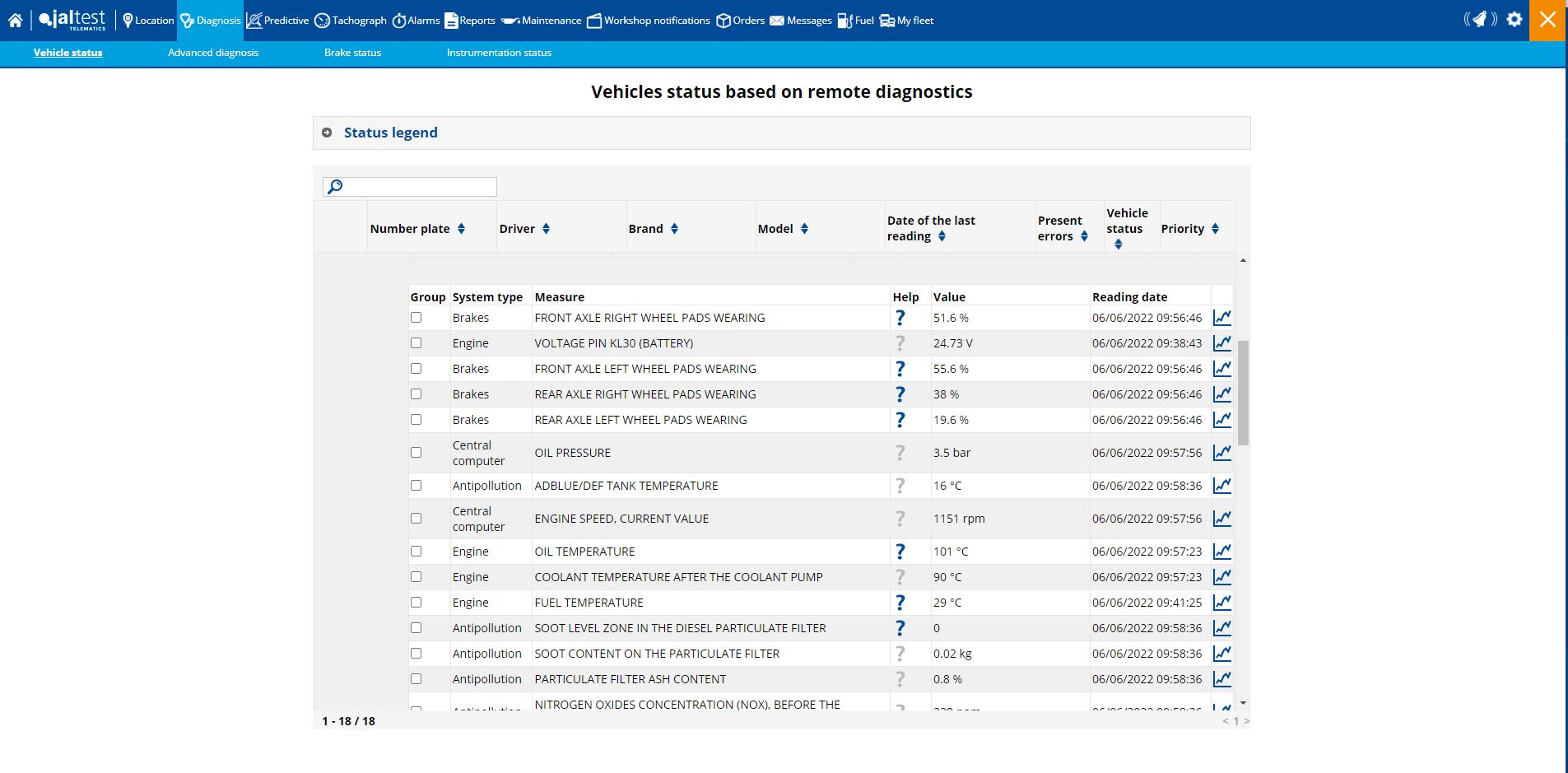

- Live data from vehicle sensors using Jaltest Telematics

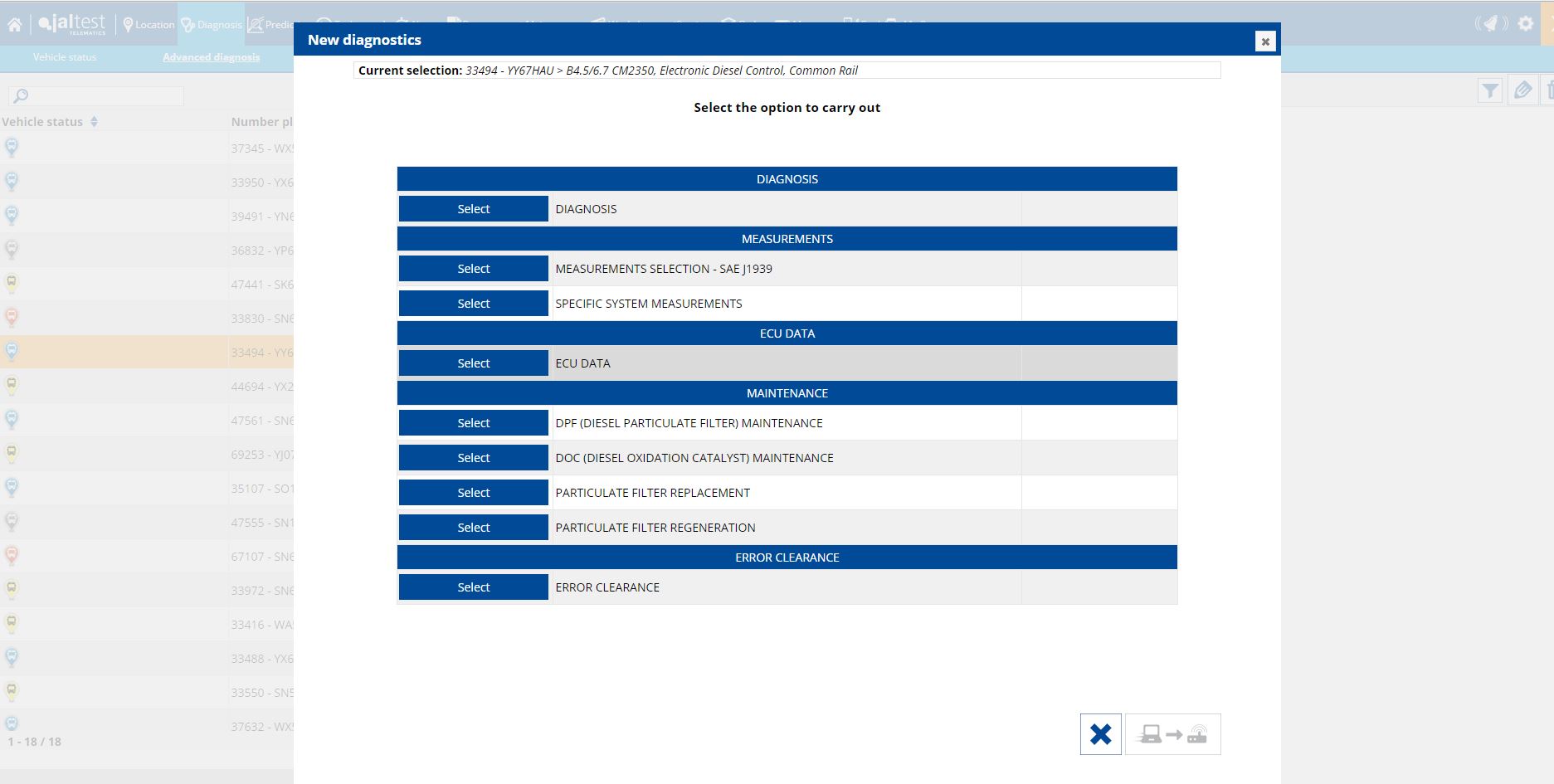

- Previous maintenance reports in Jaltest GRP (Garage Resource Planning) using the Jaltest Diagnostics tool

- Feedback from drivers about possible issues they’ve encountered

The more sources of information you can have, the better you can understand the health of your vehicles and the better you’ll be able to prevent failures.

Develop a regular servicing routine

“If it ain’t broke, don’t fix it” is not a rule you should follow when it comes to preventive maintenance. It’s sometimes the case that vehicles only get brought into the workshop when they need to be repaired but more often, the issue could have been avoided if it’d been identified earlier like, during a service.

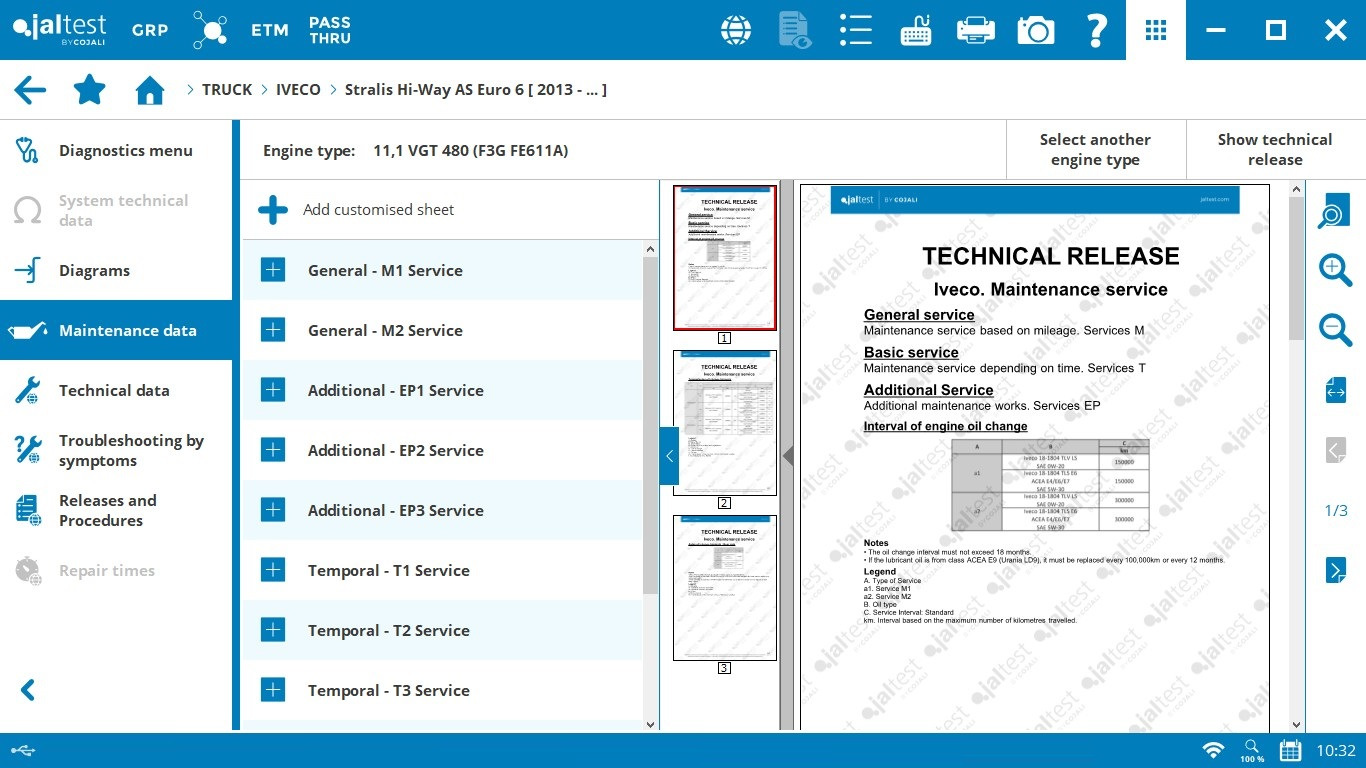

Servicing your fleet at regular intervals is the easiest way to maintain your vehicles in a preventive manner. In the workshop, using the Jaltest Diagnostics tool, your technicians can access service manuals and even look at step-by-step guides for all of the common service tasks that need to be performed on a regular basis. Doing this will go a long way in making sure that your vehicles are in tip-top condition and therefore, reducing the likelihood of failures further down the line.

Workshop technicians should also get into the habit of saving reports to GRP after they’ve performed maintenance to a vehicle, recording if any faults were found and what they’ve done to rectify the problem so that fleet managers can access this information if needed.

Train the team

Training employees on how to use the technology correctly is crucial for efficiency. This includes educating fleet managers on how to use the system to support their work. And instructing maintenance staff on how to carry out maintenance tasks in accordance with the system’s suggestions.

Luckily, we provide a whole range of in-depth courses on Jaltest Diagnostics and other accompanying products.

Maintain an open line of communication with your drivers

Communicating with your drivers is a crucial element to the success of your preventive maintenance programme. After all, the way that the vehicles are driven has a massive impact on the vehicle’s overall health. Not to mention that most faults occur while on the road. So, keeping in regular contact with the drivers allows you to instruct them accordingly.

Being able to tell them about any issues that occur while they’re driving is a huge advantage, enabling you to take action before it’s too late.

For example, you’ve noticed the soot content levels are too high in the DPF (diesel particulate filter) and continuing to drive may cause the vehicle to go into reduced power mode. In this case, you could tell the driver to pull over and then you can perform a DPF re-gen procedure remotely, avoiding a potential breakdown.

You can also view statistics related to driving style such as harsh acceleration-brake events, choice of route and fuel consumption. So, you could also feed back this information to the driver, allowing them to optimise their driving style and reduce stress on the vehicle.

Refine and optimise the system

Once the programme is operational, it’s crucial to continuously monitor and improve it. This entails routinely evaluating maintenance data, assessing performance metrics, and adjusting the software as necessary to make sure that it’s meeting your fleet’s needs.

Out of the box, Jaltest Telematics gives you AI-predictive health warnings so you can take action and address problems before they occur. But, using the ODF portal, you can go one step further by setting up specific alarm notifications to warn you if sensor readings exceed normal parameters so you know if there’s a faulty component. This is a key step to implementing an effective predictive maintenance strategy with Jaltest.

Final thoughts

Even though, implementing a preventive maintenance programme can be a challenging undertaking – it’s more than worth the initial investment. With careful planning, efficient execution, and continuous improvement, it can help you optimise fleet performance and lower long-term maintenance costs.